Cut And Sew Manufacturers for Your Apparel Needs

COREOFUS can assist you with product development, sampling, and production of your clothing line or label, from ideas to production to distribution. Our pattern-designed team carefully cuts and sews the different components of your custom design together using the exact fabric you choose. It will be easy for your customers to appreciate your brand when you engrave perfection on every product.

COREOFUS manufactures custom sports apparel in the USA using various cut and sew methods. By partnering with one of the best cut and sew manufacturers, you get entirely customized garments crafted from raw materials and stitched by highly skilled seamstresses to perfection. Cut and sew garment production goes beyond cut and sew blank t shirts – you make the garment from start to finish, from fabric choice to stitching. Providing your brand with custom apparel is the ideal way to go above and beyond your competition.

COREOFUS is a cut and sew manufacturing company committed to creating high-quality garments utilizing its years of experience in manufacturing. Our strong capabilities also allow us to work with small businesses and start-up fashion lines, as we can handle large orders.

Our Cut and Sew Services

- Pattern and Design

- Sample and Prototype

- Sourcing and Production

- Assisting Other Brands with their Cut and Sew Services

- Design, Produce, and Deliver

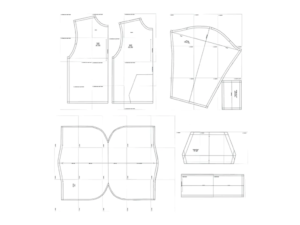

Design and Pattern Process

The process of pattern creation is based on developing patterns from procedural drawings. The measurements of the pattern are entirely customizable. Also, we work with you to make the changes and aspire to satisfy you with the results. We aim to ensure that your clothing’s measurements and cut are consistent across all sizes (S, M, L, XL, etc.) and large fashion companies. Once our cut & sew manufacturers finish your pattern, we take your ideas and turn them into a design that can be cut and embroidered.

PATTERN TYPES

Basic Patterns

The beginning of the manufacturing process starts from going back to the basics and that is why basic patterns are important. The custom cut and sew manufacturers rely on the basic design elements of apparel that help them in understanding the following manufacturing process. When it comes to complex designs the role of basic patterns is crucial as required adjustments are done on paper before their implementation in the manufacturing procedures. It’s safe to say that when it comes to cut and sew apparel then the part that basic patterns play is undeniable.

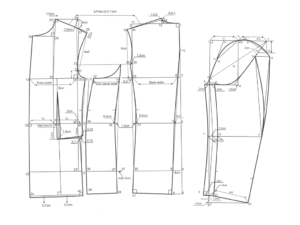

Fashionable Patterns

The importance of going back to the drawing board stays intact even if it’s about fashionable clothing products. The cut and sew services rely on complex design management techniques to encounter patterns that are categorized as fashionable patterns. The detailing that is required in the manufacturing of fashionable clothing products calls for unique manufacturing procedures to follow.

Special Tailoring

When manufacturing various products cut and sew apparel manufacturers are open to following the unique customer requirements that align with their respective tastes. The special tailoring methods follow the idea of making necessary adjustments to a pattern that would later be turned into a clothing product. The special tailoring methods might include different size adjustments and alterations of design to fit the needs of a client. The cut and sew manufacturer’s low minimum pricing might differ if any further adjustments are made in the design of a pattern.

Women Special Patterns

The clothing industry is filled with fashion trends that take the industry by storm and changing clothing trends require special pattern designs. The women’s special patterns allow the manufacturers to follow the rapidly changing course of the clothing circle and provide the clients with clothing products that not only match their taste but the ongoing spree of trends. The custom manufacturing landscape is filled with cut and sew apparel manufacturers that can offer the finest quality along with the unmatchable pricing for each customized pattern.

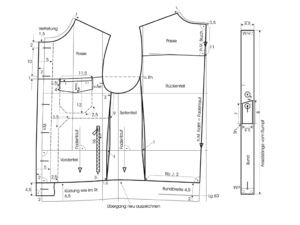

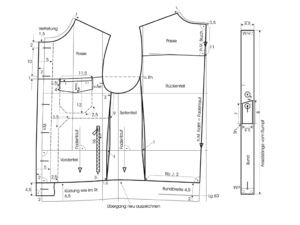

Design and Fabric Finalization

We are responsible for finalizing all of the materials required for your clothing brand. We consider the fabric, trim, and other accessories that will be required. When the design is complete, we will send you a tech pack, and if you are satisfied with the measurements and design, bulk production is a go.

Samples Finalization

Cut and sew manufacturing is not easy for any sports clothing brand, especially at the beginning. You should always appreciate the importance of selecting a professional cut and sew contractor for your garment production.

We first create a sample of your clothing line and send it to you before we start mass production. We also use this method to reduce the number of errors and break any barriers in communication between you and us, so you can have a sense of the product you will receive in bulk. A sample product will be produced in bulk after you approve it. To get your product to market faster, you can rely on us to proceed with our process quickly.

Cut and Sew Process

To get your clothing customization done, the fabric you choose and the pattern you approve will be cut and sewn according to the pattern you decide. Each garment item is sorted by size, color, and number before it is stitched or sewn together.

The most important part is the management of sewing machines. A bundle of cut pieces is given to each department, and the cut pieces are instructed to be sewn into the same section of the garment before passing it on to the next department.

Quality Assurance and Testing

COREOFUS has the most experienced team of cut and sew shirt manufacturers who consider quality before anything. Our custom cut and sew clothing services always satisfy customers. The cut and sew manufacturing process is carried out by us, and our quality checks are carried out and reported to the fashion house. As part of our quality assurance check, we ensure that all our products undergo testing three to four times before they are shipped to meet the product requirements, and we also follow up on the quality process and customer requirements ensuring that the products are checked three to four times before shipping to ensure customer satisfaction.

All of Your Cut and Sew Requirements

You can choose from various options when you design your t-shirt, hoodie, jeans, and many other items you would like to customize. Before we can recommend the best fabrics on the market to satisfy a customer’s cut and sew garments needs, we first need to understand their cut and sew imperatives. Our team will work with the customer to offer them the best choice of fabric, print, and pattern to ensure they get the best value. No matter the design’s complexity, the cloth is cut into panels for screen printing, embroidery, and sublimation.

Cut and Sew Machinery

The most common machines are the Sewing Machine, the Cutting Machine, and the Threading Machine. As the primary machine for both the Cut and Sew process, the sewing machine assists with creating the individual seams that make up the final product. It is used to stitch the seams together to create the final product. The fabric is cut in a straight line using the Cutting Machine, which is usually accurate within a thousandth of an inch of a guideline. COREOFUS is fully equipped with the latest technology to manufacture the products. We use a few machines to cut and sew hoodies and shirts. We have advanced sewing machines, cutters, and a sewing machine foot to complete the processes.

Create Your Own Clothing Brand with Custom Clothing Manufacturers

COREOFUS will make everything easier for you with our processes and services. We can help you with your clothing requirements since our specialty is in creating premium quality custom clothes for clothing brands. Being the leading custom apparel manufacturers with a superior sense of global apparel knowledge, we can save your brand from setbacks. Also, our advanced means of sourcing fabric and producing clothes can guarantee your success in the apparel industry.